Since the official release of Qiaotian Intelligence's one-stop automatic mold change solution, Qiaomei has successively received many product inquiries about automatic mold change: Without bolts and hydraulics, is magnetic mold change really safe? Next, Qiaomei will take you into the automatic mold change system through two customer cases.

01 2400T Magnetic Die Change Project of a Mold Factory

A mold factory currently uses the pressure plate mold change method, relying on manual operation. Each set of molds requires the loading and unloading of 16 sets of high-strength bolts, with a single mold change taking up to 1 hour. Due to differences in mold specifications, frequent adjustment of the pressure plate is required, resulting in a positioning accuracy fluctuation of ±0.1mm. More critically, pipeline connection requires the simultaneous operation of 5 technicians, with an incorrect insertion rate as high as 5%.

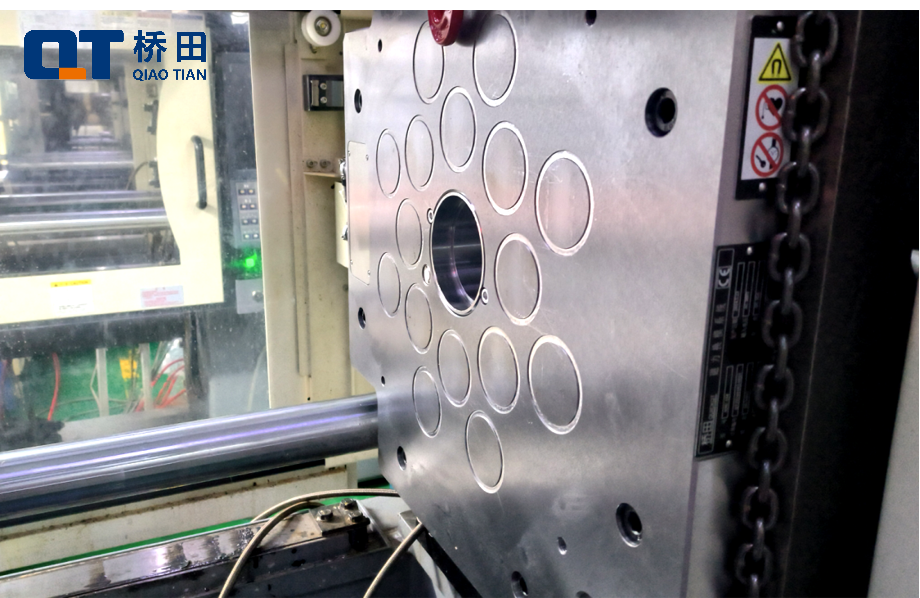

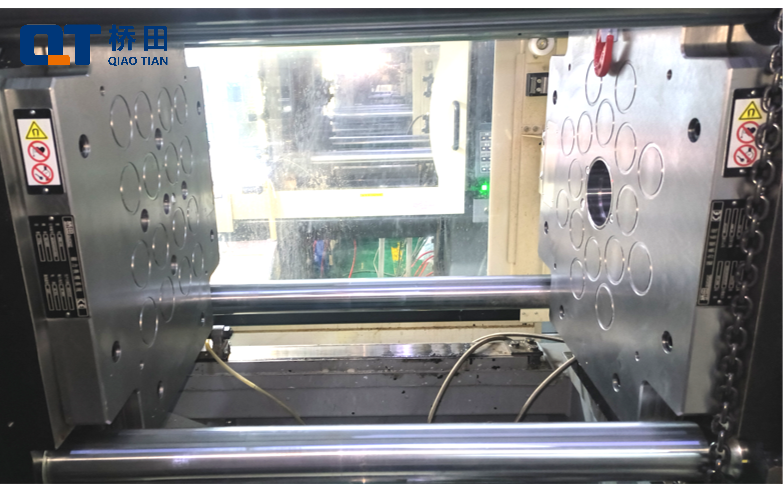

According to the actual production needs of customers, Qiaotian Intelligence is equipped with an automatic mold change solution consisting of magnetic plates and energy combination module products.

Firstly, the magnetic plate achieves rapid magnetization/demagnetization of 2400T-class molds in 3 seconds by adopting a high-permeability alloy magnetic pole matrix, with a magnetic attraction density reaching 16Kgf/cm2, accommodating a thickness tolerance of ±50mm, and completely eliminating the restrictions of clamping plate specifications. Among them, the magnetic module uses electro-permanent magnet hybrid technology, which can still maintain the mold clamping state during sudden power outages (without external power supply), avoiding the risk of mold falling.

In addition, the system is equipped with a built-in 64-zone pressure sensing network, which displays the clamping force distribution and safety factor in real time, automatically calibrates the risk of unbalanced load, and prevents problems such as uneven force on the mold leading to easy deformation and high risk of hydraulic leakage.

Considering the customer's pipeline connection issues, the Qiaotian team has highly integrated energy sources such as water, oil, gas, and electricity, that is, one plug-and-play operation completes the plugging and unplugging of all connectors of the entire mold, and a single person can complete the connection of all media in 3 seconds. At the design level, the modular plug precisely matches the guide pin, preventing incorrect or missed plugging and avoiding downtime losses caused by interface errors.

After the implementation of this solution, the number of mold change operators has been reduced from 5 to 1, and unexpected downtime caused by mold change failures has been reduced by 95%.

02 110T Magnetic Die Change Project of a Medical Products Factory

The current situation of a medical product unit is that a single workstation has up to 4 types of mold changes, with an average of 1-2 mold changes per day, and each mold change takes 40-60 minutes. The traditional mold clamping method not only has low efficiency but also generates debris due to metal friction, polluting the production environment. Meanwhile, with the bolt locking method, the mechanical restraint of the guide column restricts the free expansion of the template, posing risks of mold distortion and misalignment due to thermal expansion differences, which affects product accuracy.

According to the actual production needs of customers, Qiaotian Intelligence adopts a magnetic adsorption automatic mold change solution.

First, by using a magnetic plate to adsorb the mold instead of mechanical clamping, the problem of environmental pollution caused by metal debris for customers is completely solved. Meanwhile, the permanent magnetic adsorption force automatically adjusts with temperature, avoiding stress concentration, allowing the mold to expand freely, and eliminating the need for custom fixtures or adjustment of the mechanical structure. This addresses the issue of mold misalignment caused by temperature difference deformation due to traditional bolt locking for customers.

2025-04-25

2025-04-25

27

27